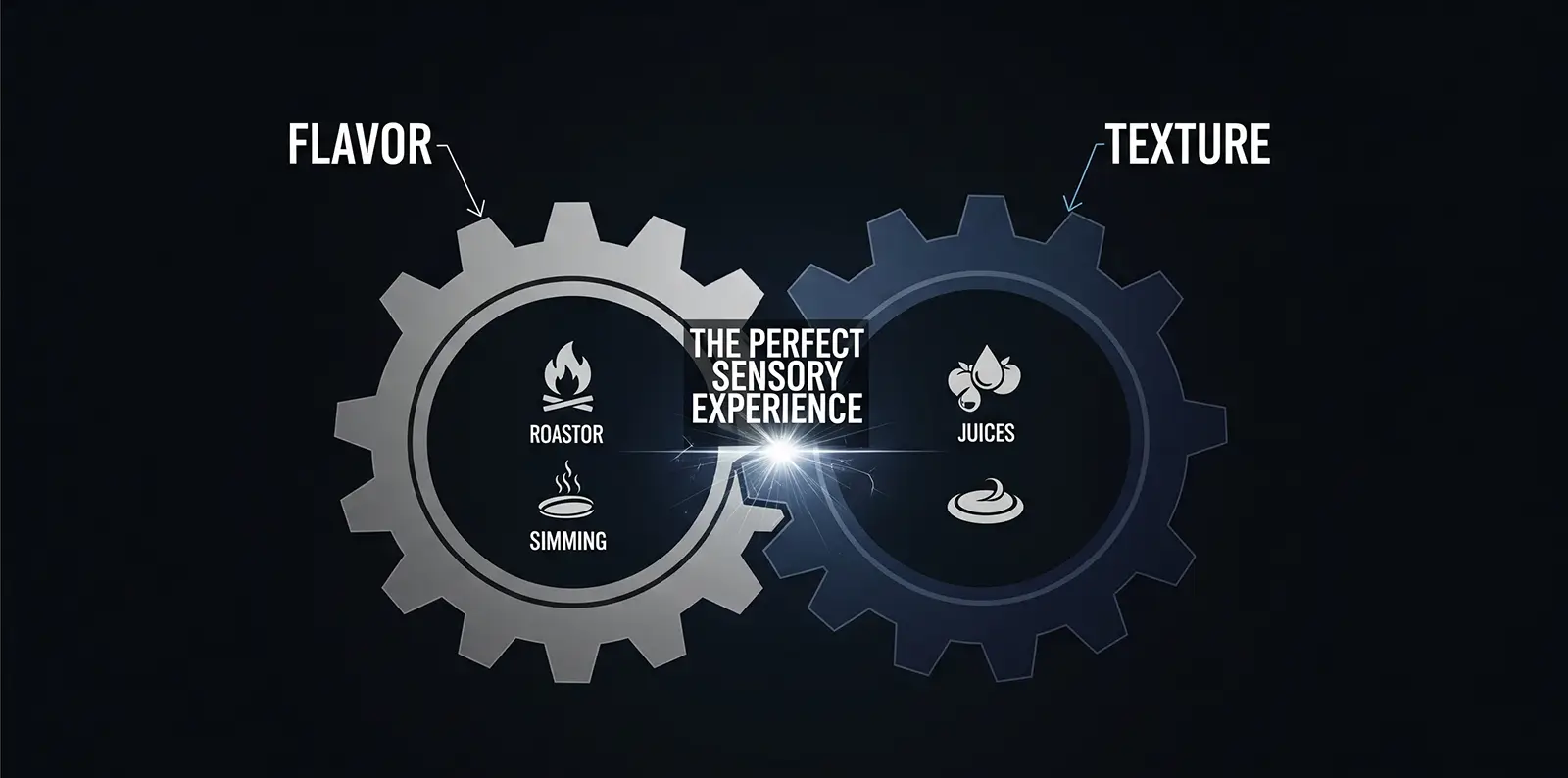

Consumers crave the deep, complex flavors that develop over hours of slow cooking and roasting. We call this authentic sensory depth the "Flavor of Time." Our thermal process reaction flavors are created through the Maillard reaction—a natural chemical process between amino acids and reducing sugars under heat that generates the rich, savory, and "roasty" notes associated with grilled meats, baked bread, and roasted coffee. By precisely controlling this reaction, we can replicate the authentic savory foundation that consumers associate with richness and home cooking, delivering it without the prohibitive time and cost of traditional methods.

An authentic flavor foundation requires a flawless textural matrix to deliver its full impact. Our portfolio of natural texturizers and mouthfeel enhancers is designed to build the perfect eating experience from the ground up, solving the toughest formulation challenges in today's market.

We provide plant-based solutions that deliver a rich, creamy, and indulgent mouthfeel for dairy alternatives, soups, and sauces. Using hydrocolloids like gellan gum and xanthan gum, our systems replicate the smooth, palate-coating sensation of full-fat dairy, replacing its functionality to create a satisfying experience.

Our carbohydrate- and protein-based ingredients mimic the lubricity and richness of fat, allowing for significant fat reduction in products like baked goods and processed meats without sacrificing sensory quality. These mimetics bind water and imitate the physical properties of fat, ensuring that healthier products remain indulgent and satisfying.

We offer specialized solutions for meat and plant-based meat alternatives that dramatically improve water retention to create a juicy, succulent bite. Ingredients like methylcellulose form a heat-set gel during cooking, trapping moisture and fat that is released upon chewing for a sustained, flavorful experience from start to finish.

A major challenge in plant-based meat is delivering sustained juiciness and connective bite without animal fat. Many analogues fail because moisture migrates away from the bite zone or volatile savory notes evaporate during cooking. Our integrated approach solves both the flavor and physical aspects.

Three-part solution:

Outcome: Initial impact on first bite, a sustained juicy body through chewing, and a clean finish without residual off-notes.

Case study (short):

Product: Plant-based burger prototype

Goal: Increase perceived juiciness score by 30% while reducing total fat by 40%.

Approach: Reformulated with a 0.3% roasted reaction flavor base + 1.5% juiciness matrix + 0.8% fat-mimetic emulsion. Pilot grilling at 180°C for 5 minutes each side.

Result: Sensory panel reported +33% juiciness, improved mouth-coating, and lower residual off-notes vs. control.