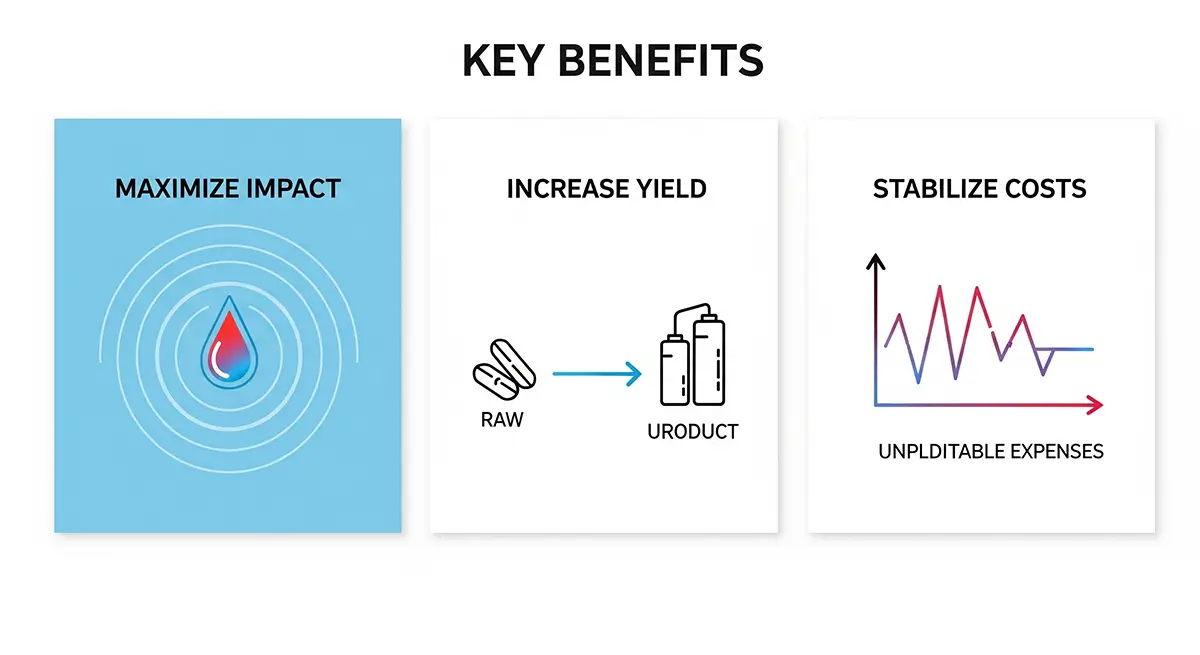

Global raw-material volatility and tightening margins mean manufacturers must squeeze more value from the same inputs. Too often “flavor” is treated as a purely sensory line item—yet when engineered correctly, flavor and functional ingredient selection become powerful levers for cost-in-use, yield improvement, and supply-chain resilience.

At Ruikelai we translate sensory science into financial results: fewer grams per SKU, less cooking shrinkage, lower reliance on volatile commodities, and formulation strategies that prioritize margin-first performance while preserving brand taste profiles.

What it is: High-intensity process and reaction flavors that deliver the same or better sensory impact at a fraction of the dosage.

Why it matters: Lower dosage = lower cost-in-use and less SKU waste.

Quick bullets:

Typical inclusion: 0.1–0.5% vs 0.5–2% for commodity spices.

Easier quality control due to standardized concentrates.

Reduced freight and storage costs (less volume per batch).

What it is: Functional protein systems and process aids that improve water- and fat-binding, reduce cooking shrinkage, and stabilize emulsion structure in meat, poultry, and bakery systems.

Why it matters: More finished product per tonne of raw material — immediate revenue and margin uplift.

Quick bullets:

Typical effects: reduced cooking loss, improved texture, more consistent slice yield.

Plant-level benefits: fewer reworks, more sellable product, less waste.

What it is: Flavor extenders and enhancers that replicate or support expensive commodity notes (e.g., vanilla, certain dairy/cheese notes, and fragile spice signatures) with stable, lower-cost alternatives.

Why it matters: Protects margins from commodity spikes and simplifies procurement.

Quick bullets:

Provides consistent flavor across seasons.

Lowers price sensitivity and procurement risk.

Client brief: Emulsified sausage producer with high cooking loss and tight margins.

Intervention: Replace standard binders and adjust formulation to include Ruikelai functional soy protein system at 2% inclusion, plus a complementary high-intensity process flavor to maintain flavor profile while reducing seasoning dosage.

Results (client data):

Cooking loss before: 12% (i.e., finished product = 100% − 12% = 88% of raw).

Cooking loss after: 5% (i.e., finished product = 100% − 5% = 95% of raw).

Absolute improvement: 12% − 5% = 7 percentage points.

Example, per 1,000 kg raw material:

Before → finished = 1,000 × (1 − 0.12) = 880.0 kg.

After → finished = 1,000 × (1 − 0.05) = 950.0 kg.

Net additional finished product = 950.0 − 880.0 = 70.0 kg (an extra 70 kg output).

Relative increase vs. previous finished weight = 70.0 ÷ 880.0 = 7.95% more sellable product.

Financial impact (illustrative): the client reported a 15% net reduction in total formulation cost when accounting for the ingredient cost of the soy system and flavor concentrate. This included savings from lower seasoning usage, reduced shrinkage, and fewer reworks.

Why this matters: The extra finished kilograms are immediate revenue (or volume to reallocate across SKUs) and the lowered formulation cost improves margin per finished kg. In many cases this creates payback in a single production cycle.